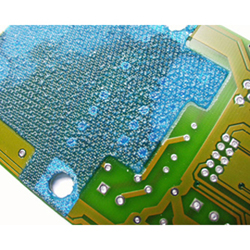

Peelable mask PCB is kind of printed circuit board with peelable solder mask protected for some area.

Sometimes, a certain area of PCB board needs to protected special during surface finishing or assembly process,

which is peel-able solder mask needed. Peelable mask, also as strippable mask or blue-mask is applied by screen printing,

act as in-process production, such as lead-free) soldering processes like wave soldering,

reflow soldering or hot-air solder leveling (HASL), and will removed after these PCB fabrication and assembly.

Peelable mask PCB is required by many of our customer because it is more economical compare taping,

and peelable solder resist could accept high temperature and good peel-ablility.

General features and advantages of the peelable solder mask range are:

- Time an cost saving process compared to taping

- Protection of complex structures and shapes by efficient screen-printing

- Protection of selected areas on the PCB during various finishing or assembly processes

- Protection (tenting) of PTH

- Overprinting of carbon inks

- Resistance in plating processes (e.g. electroless/electrolytic Copper or Tin plating)

- Protection during Flex or Flex-Rigid processing

- Highest temperature acceptance and good peel-ability

IblueBoard specializeds in PCB prototpe, medium volume to mass production with Quick turn...

IblueBoard specializeds in PCB prototpe, medium volume to mass production with Quick turn...